It's an understatement to say that managing a data center is challenging. Data center managers are expected to do more with less, including protecting rapidly expanding volumes of data, managing a growing number of applications, maintaining availability and uptime, reducing expenses, improving space utilization, managing energy usage and costs, and more.

Two factors that can make life for data center managers a lot easier (or harder), depending on how you manage them, are heat and vibration.

Today, storage vendors are squeezing more storage density into each rack, and data center architects are squeezing more racks into each data center to maximize real estate and decrease TCO. The challenge is that the more storage density you pack in, the hotter it can get, and the more likely vibrations will shake things up. This can exacerbate all of the challenges mentioned above.

How can you keep your data at an optimal temperature with minimal vibration and thus deliver optimal performance all at a reasonable cost? A starting point is to look at the enclosures themselves.

Why Temperature Matters in the Data Center

Effective cooling is today’s challenge for very dense storage enclosures. Typically, air is drawn into the box from the cold aisle in the data center. This air passes over successive rows of drives and gets warmer with each row. The drives closest to the cold aisle stay relatively cool, while those at the back can run at significantly higher temperatures.

To counteract this, one approach is to turn up the fan speeds. In some data centers, additional blowers are added to the cold aisle end of the enclosure to help move air even faster. However, this results in higher power requirements, higher energy costs, higher noise levels, and higher vibration, all of which can lead to performance degradation and compromised data reliability.

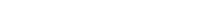

A New Approach to Cooling – Start with the Storage Enclosure

An alternate approach is to select a solution that divides the storage enclosure into two thermal zones, with rows of drives in the front and in the back. Western Digital’s ArcticFlow™ takes this approach (see below diagram). Like traditional design, cool air is drawn into the front zone from the cold aisle, but instead of being drawn over the rear zone, the air is then ducted around the sides of the enclosure and exhausted to the hot aisle at the rear. A cool air tunnel brings cold air directly into the center of the enclosure to cool the rear zone.

Western Digital’s ArcticFlow technology divides the storage enclosure into two thermal zones and tunnels cold air through the center to cool the drives furthest from the cold aisle.

This enables lower fan speeds to maintain cooling, resulting in less power consumption, lower noise levels and less vibration.

In testing, using this approach required just over half of the cooling power per drive slot as a similar product without it. To put this into perspective, using California energy costs and typical data center efficiency, the savings would be about $1,500 per enclosure over a typical five-year system lifecycle. In a large data center with 20,000 drives, this could be as much as $300,000 savings in energy costs.

In another test, 30 percent of the drives in an enclosure that did not use this cooling approach ran at an average of 13 degrees Celsius hotter, which based on projections would mean they were likely to have 13 percent more drive failures over time due to elevated temperatures.

Cooling thus enables lower TCO by running data center racks at significantly lower temperatures which translates into lower energy costs and lower likelihood of failures.

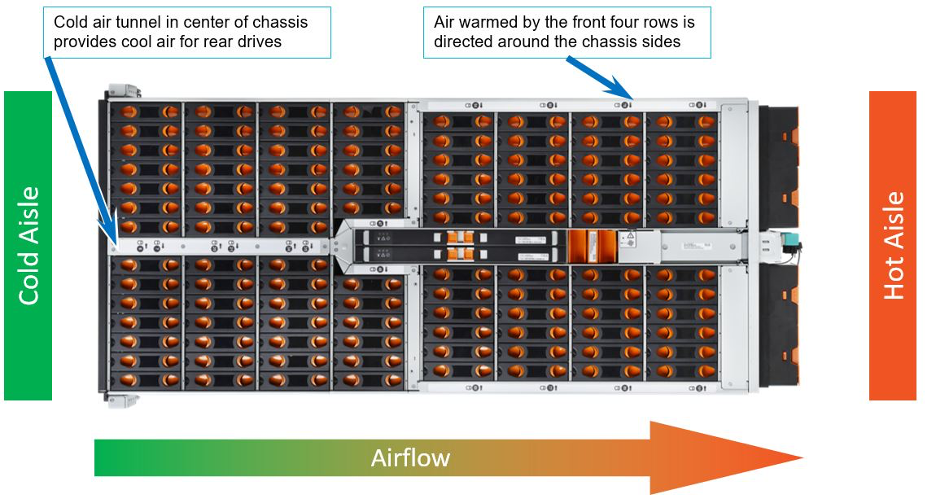

Innovative Design for Storage Enclosures Reduces Field Drive Returns by 62%

Learn how innovation in the storage enclosure hardware can actually pay great dividends in terms of cost, performance and reliability and learn how Western Digital’s deep knowledge of the interaction of devices and systems can help ensure an efficient design.

Download NowImpact of Vibrations on Data

Ever seen the video where a guy in a data center shouts at a rack of hard drives to see the impact of vibration on latency? “Don’t shout at your JBODs! They don’t like it!,” he exclaims.

With today’s extreme storage density, drive vibration control in storage enclosures is more critical than ever. The storage enclosures housing your data may determine how much drive vibration interferes with application performance. Areal density improvements include squeezing HDD tracks closer together, which makes them more susceptible to errors occurring with vibration.

What happens is that external shock and vibration can cause HDD heads to go off track, resulting in performance delays while the head resettles and waits for the correct sector to come around again for reads or writes to resume. The HDDs are smart enough to avert data corruption, sending the wrong data or writing data in the wrong place, but while the HDD head waits, latency is introduced and application performance is reduced.

Vibration can be caused by other factors as well. When other shelves in the rack are being serviced, closing the door, or even a fork lift passing by can all cause external shock and vibration. In a dense array of HDDs, adjacent drives seeking at high speed can also induce vibration into their neighbors. And, as a result of the need for cooling, fans can transmit vibration through the chassis and also through the air as sound energy. In all of these cases, vibration can lead to latency which in turn slows application performance.

As a leading manufacturer who understands the characteristics of HDDs, Western Digital’s patented IsoVibe™ technology offers one approach to combat vibration within a storage enclosure. Precise cuts in the baseboard act as a suspension for the drives providing isolation from the vibration transmitted from one drive to another. Vibration-isolated fans also minimize vibration and noise transmission. Working together, IsoVibe and ArcticFlow enable lower fan speeds, which mean less vibration. This allows performance to be maintained across the enclosure, even when all the drives are working hard. It will also help future generation HDDs with even tighter track densities to operate in dense enclosures with minimal performance degradation.

Proactively managing vibration ensures that drive heads are less likely to be thrown off track, and therefore more likely to maintain desired performance. Testing has demonstrated 60 percent less operational vibration when using IsoVibe technology. And, the combination of these innovations can lead to lower drive return rates. In another analysis, using ArcticFlow and IsoVibe resulted in 62 percent less drive returns compared to the previous generation platform without these innovations using the same drive family, same vintage, and the same capacity point.

Density, Heat and Vibration – Can’t We All Just Get Along?

It can be a balancing act, but with the right strategy and tools in place, data center architects can reap the rewards of higher density storage while fending off the threats of heat and vibration to their data. There are innovations available today that contribute to improved cooling, lower vibration and lower power consumption that pays off directly in terms of lower utility bills and ultimately reduced carbon footprints. Understanding cooling and vibration management enables improved performance, reliability and cost savings.

Click here to learn more about optimizing your storage enclosures for better cooling and vibration.